In modern manufacturing, filling machines play a crucial role as indispensable equipment. Whether in the food, pharmaceutical, cosmetics, or other industries, filling machines are responsible for precisely dispensing products into packaging containers, ensuring product quality and consistency.

As illustrated, the white machine on the left represents the traditional manual filling machine, while the black machine on the right symbolizes the improved version, which will be discussed in detail in this article.

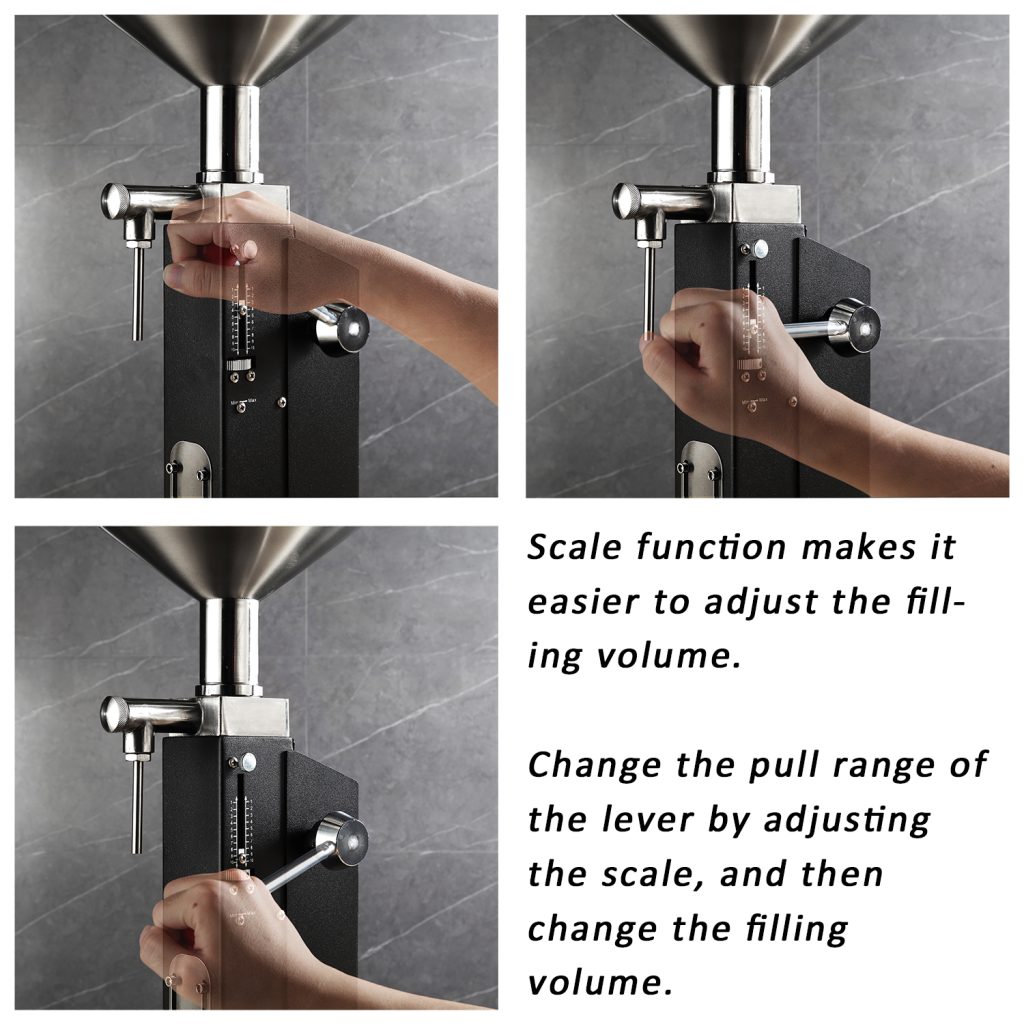

The improved manual filling machine functions on the same principle as the traditional machine for dispensing materials — by adjusting the filling volume through controlling the range of lever movement.

However, what distinguishes it is the enhanced lever-range control mechanism and the incorporation of a scale feature.

Furthermore, a shelf has been introduced below the dispensing nozzle, allowing for adjustable height positioning.

It is constructed using a combination of food-grade stainless steel and regular iron materials.

The hopper, internal core components, and other parts that come into contact with the materials are all made of food-grade stainless steel to ensure materials safety.

The minor components, on the other hand, are made of regular iron with rust-proof paint to minimize production costs and enhance the cost-effectiveness of product.

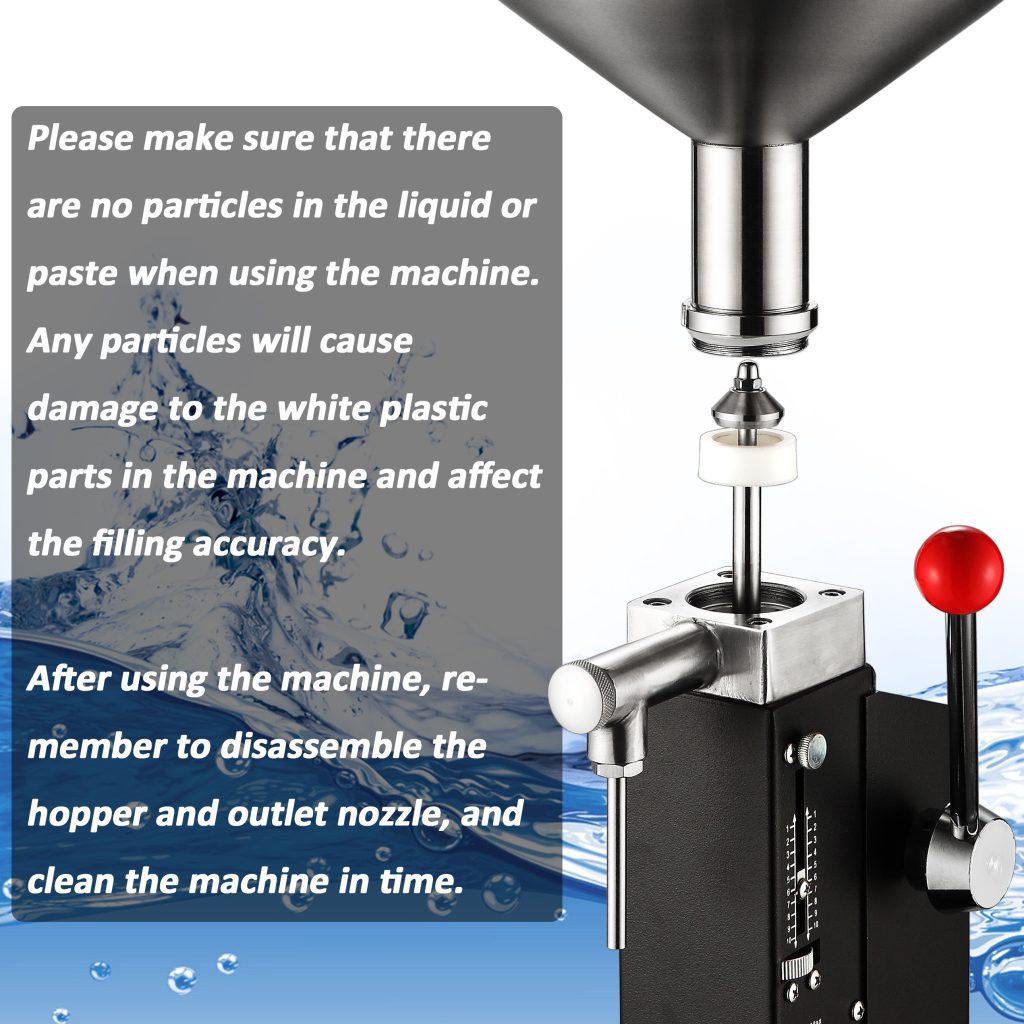

Similar to the traditional machine, the improved version is also suitable for filling no-particles liquids and pastes across various industries.

But why is it only for no-particles liquids and pastes?

This is because of a crucial component inside the machine – the ceramic piston. It ensures precise filling volumes. As the piston is made of ceramic material, any particles can potentially cause wear and even minor wear can lead to irregular filling volumes.

Moreover, some residue left inside the machine can dehydrate and solidify, which may further contribute to wear on internal parts. Therefore, it is essential to clean the internal components of the machine after each use.

It’s worth mentioning that the traditional machine also encounters this issue. Looking forward to manufacturers developing methods to overcome this challenge.

There is another type of manual filling machine available in the market that shares the same overall structure as the traditional machine. However, the manufacturer replaced the material of its hopper with transparent plastic.

While plastic material is indeed more cost-effective compared to stainless steel, the expense of plastic molds is considerably high. After factoring in the mold cost, the manufacturing cost of the machine does not decrease significantly. Furthermore, plastic material is more prone to breakage and has lower heat resistance compared to stainless steel.

The main advantages of this design revolve around the transparent hopper, which allows users to conveniently assess the remaining quantity of materials inside. Additionally, it contributes to reducing the overall weight of the machine.

(Personally, I believe that replacing the hopper with transparent plastic material has more disadvantages than advantages. If you have a different opinion on this matter, feel free to leave a comment in the comment section.)

Finally, I will include the purchasing link and a video demonstration of the improved manual filling machine.

If you are considering purchasing a manual filling machine and have taken the time to explore the market, you will find that the improved machine is not more expensive than the traditional machine. In fact, it may be more cost-effective.

PURCHASE LINK OF IMPROVED MANUAL FILLING MACHINE

PURCHASE LINK OF TRADITIONAL MANUAL FILLING MACHINE WITH TRANSPARENT HOPPER