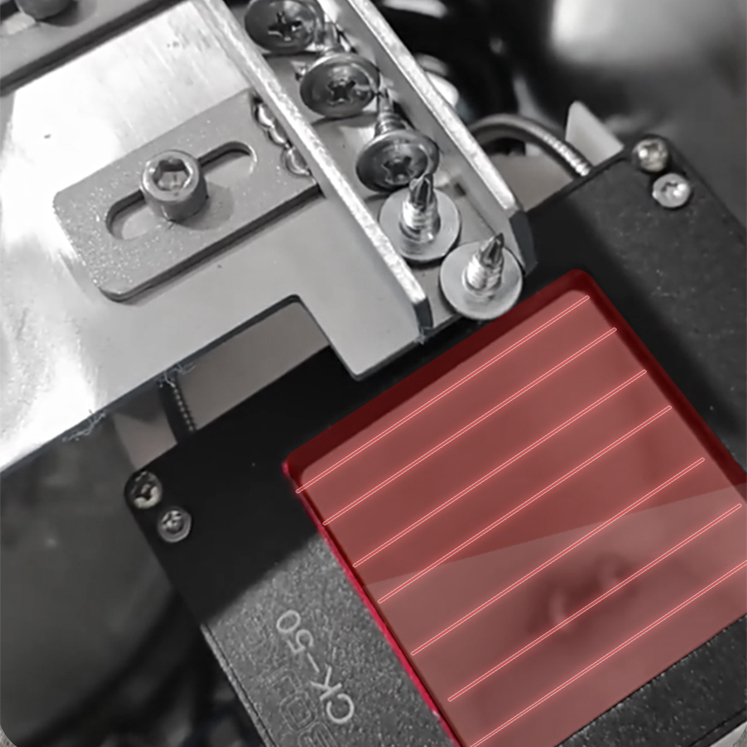

The laser-counting filling machine is similar to the weighing filling machine as they both utilize vibration feeding to deliver materials into the central area. However, the laser-counting filling machine incorporates a laser sensor between the central area and the vibration feeder. When the materials pass through the feeder and enter the central area, the laser sensor detects and counts them. Once the count reaches the predetermined value, the machine stops the vibration feeding and proceeds to fill the materials into the container.

The greatest advantage of the laser-counting filling machine over the weighing filling machine lies in its ability to accurately sense and count each individual material, eliminating the quantity errors that may arise from weighing. For instance, when you need to fill 90 capsules per operation, the weighing filling machine may result in filling 91-93 capsules per cycle, which can accumulate additional production costs over time. On the other hand, the laser-counting filling machine completely avoids such cost increments.

However, it is important to note that the laser-counting filling machine is not suitable for handling materials such as powder, liquid, or paste.

The laser-counting filling machine, with its precise counting and filling operations enabled by the laser sensor, holds wide-ranging applications across various industries. If you are seeking an efficient and highly accurate filling equipment, especially for granular materials, the laser-counting filling machine is undoubtedly a wise choice.